Specialized Flexible Protective Bags

We are one of the pioneers in the development of ESD oriented plastics and laminates. We continue to maintain the ranking as a leading supplier of superior engineered moisture barrier bags and clean room packaging.

Drypack DB 3000 series moisture barrier bag

Drypack DB 3000 series is specifically designed to provide superior moisture vapor barrier yet fully transparent. This proprietary film lamination structure enables you to see through to the contents and perform barcode scanning.

Features Benefits - Low MVTR @ <0.05g/100in2/day

- Enhanced contents protection from moisture

- Transparent

- Easy content identification and bar code scanning

- Minimal charge retention

- Safeguards static sensitive devices

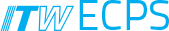

Film Structure

Drypack DB 3000 series uses film that is designed for packaging of Hard Disk Drive applications. These packaging materials have the same antistatic inside sealant layer, a very thin layer of vacuum deposited aluminum on a substrate or solid and with the moisture barrier layer to provide moisture protection.

Drypack DB 38XX series moisture barrier bag

Drypack DB 38XX series is a high barrier foil laminated film developed for semiconductor industry. It is a popular choice to vacuum pack tape and reel, IC trays or shipping tubes.

Features Benefits - Superior MTVR, < 0.0003 g/100 in2/day

- Excellent vacuum retention

- A solid Aluminum foil middle layer

- Total EMI/ESD protection

- More than 25 lbs puncture resistant

- Prevent bag puncture against sharp corners of IC tray or shipping tube

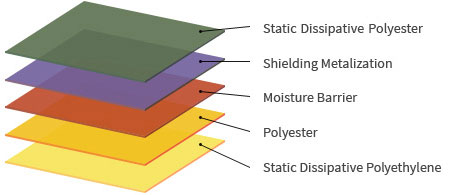

Film Structure

The film has an antistatic inside sealant layer, an embedded solid foil layer to insure against moisture vapor transmission and an outer layer selected to maximize packaging strength or vacuum retention. The embedded solid aluminum foil layer acts as a barrier against ESD, moisture vapor transmission and also provides EMI shielding from all RF signals and EM radiation.

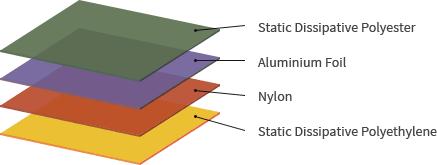

Drypack DB 33XX

A solution developed for Surface Mount devices (SMD).

Drypack DB 33XX series employs a static dissipative outer layer of polyolefin and a cost effective alternative to DB 38XX series. A solid aluminum foil middle layer and an inner layer of antistatic polyethylene are used to provide moisture vapor protection and guard contents against triboelectric charging.

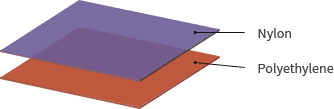

Nylon PE series

Nylon PE is ideal for packing sharp objects such as fastener where puncture resistance and durability are required. The film is transparent clear, strong and vacuum heat sealable.

Features Benefits - Reinforced with nylon

- High puncture resistant

- Transparent clear

- Contents remain visible while protected

- Readily heat sealable

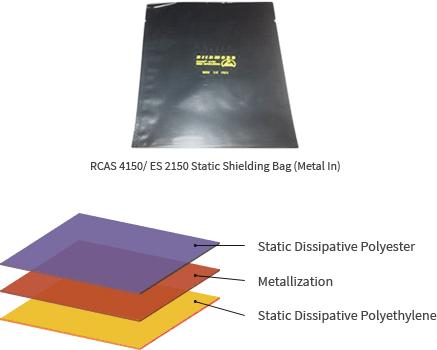

Static Shielding Bag

These packaging materials are made up of layers (a lamination), one of which is metal. The metal layer in static shielding bags is either a very thin layer of vacuum deposited aluminum on a substrate or a solid. The metal is sandwiched between the plastic layer, typically polyester (PET) and antistatic polyethylene(PE), on the other side act as a sealant layer which prevents the bag contacts from becoming electro statically charged during movement. The “buried” metal acts as a shield. Should an ESD strike the outer surface of the bag, the metal will shunt the discharge energy, spread it out over the surface of the metal and reduce its dangerous energy to a small fraction of the original charge.

Selection Chart

Brand Name Nylon RCAS 4150/ES 2150 Drypack DB 3000 Drypack DB 38XX Drypack DB 33XX Physical Properties Test Method Unit PE Bag Static Shielding Moisture Barrier Moisture Barrier Moisture Barrier Thickness ASTM D374 Mil +/-10% 2.5-8.0 3.0 3.0 3.6-7.0 3.6-7.0 Light Transmission - % +/-10% 100 40 55 None None Puncture Resistance FTMS 101C Method 2065 lbs >15 >12 >15 >25 >25 Heat Seal Strength ASTM F88-99 lbs/in >13 >10 >11 >15 >15 MVTR ASTM-F-1249-90 (37.8°C, 90%RH) g/100in2/day N/A N/A <0.05 <0.0003 <0.0003 Electrical Properties Surface Resistivity EOS/ESD S11.11 ohm/sq < 1x1012 < 1x1012 < 1x1012 < 1x1012 < 1x1012 Electrostatic Decay FTMS 101C Method 4046 sec N/A < 0.05 < 0.05 < 0.05 < 0.05 Energy Test EOS/ESD S11.31 nanojoules N/A < 20 < 15 < 10 < 10 Cleanliness Properties LPC @>0.5um counts/cm2 <3000 <3000 < 3000 <3000 <3000 Outgassing GC-MS ng/cm2 < 1709 < 1709 < 1709 < 1709 < 1709 Ionic Contamination Chloride, Nitrate, Sulphate ng/cm2 < 10, < 100, < 10 < 10, < 100, < 10 < 10, < 100, < 10 < 10, < 100, < 10 < 10, < 100, < 10

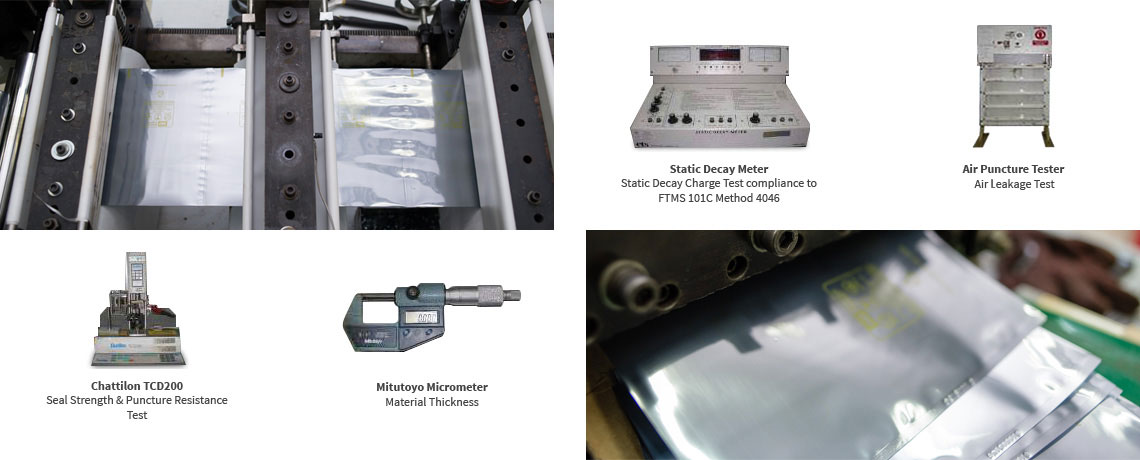

process

Our manufacturing facility has capability of producing Class 100 clean room bags and commercial grade specialized flexible protective bags. The conversion lines can cater for various bag sizes up to 36” width. We also offer customized print labeling in multi color, tear notching, lot numbering and hot stamp capabilities.

Our reliability lab has seal strength test, puncture resistance test, ESD and other mechanical test capabilities to ensure defect free products.

Quality Control

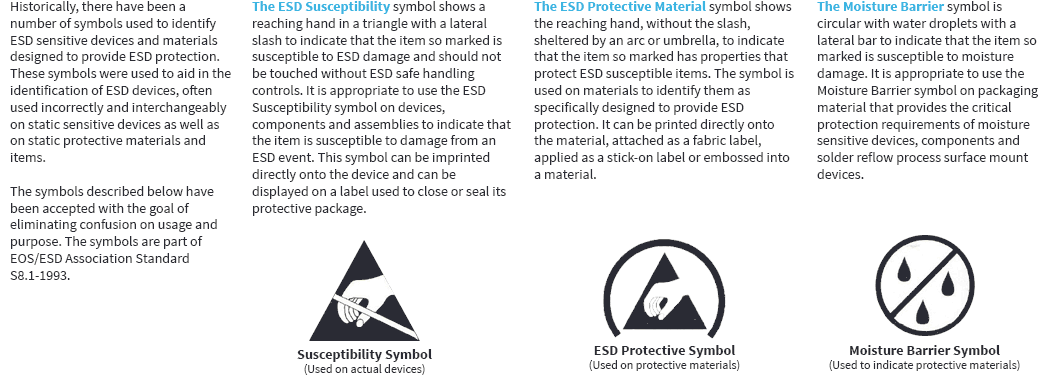

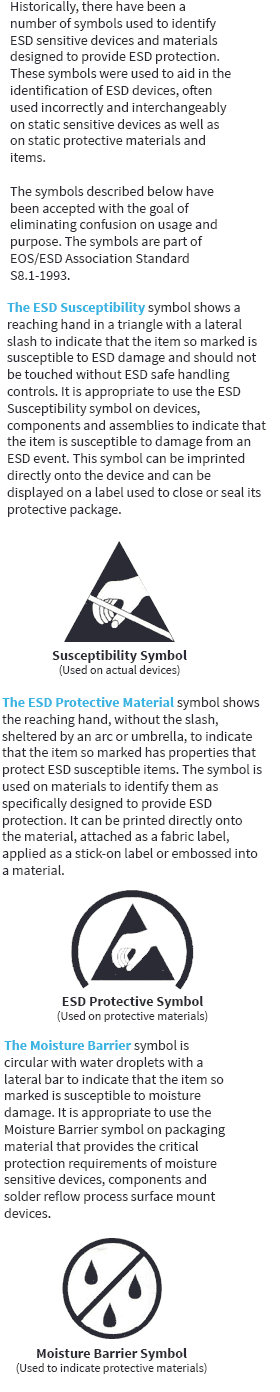

ESD & MOISTURE PROTECTIVE SYMBOLS

Application / Market served

Recommended Brand Name Nylon PE Bag RCAS 4150/ES 2150

Static ShieldingDrypack DB 3000

Moisture BarrierDrypack DB 38XX

Moisture BarrierDrypack DB 33XX

Moisture BarrierMarket/Application Served HDD

SEMICONDUCTOR

WAFER

PCBA

PUNCTURE PROTECTION

CORROSION PROTECTION

** Available in commercial grade and Class 100 clean room grade